Table Of Content

Design for Manufacturing refers to the practice of designing products in a way that optimizes their manufacturability. The primary goal is to minimize production costs, reduce complexity, and ensure product reliability while adhering to quality standards. This involves making decisions in the design phase that will simplify the production process, like choosing readily available materials, reducing the number of parts, and considering ease of assembly. Thus, designing products using DFM creates a solid plan for product development before the design process even begins.

The future of design and manufacturing

Boothroyd Dewhurst DFM Concurrent Costing 3.0 Supports OEM Supply Chain Partnerships with Science-Based ... - Business Wire

Boothroyd Dewhurst DFM Concurrent Costing 3.0 Supports OEM Supply Chain Partnerships with Science-Based ....

Posted: Tue, 19 Sep 2017 07:00:00 GMT [source]

3D printing also has the potential to expedite the development of pharmaceuticals and enable on-demand production. To better prepare for surgery, 3D printed models mimic the anatomy, size, texture and color of real organs, tissues and lesions. Engineers and product designers using a DFM approach by collaborating in a modern office.

What is Design for Manufacturability?

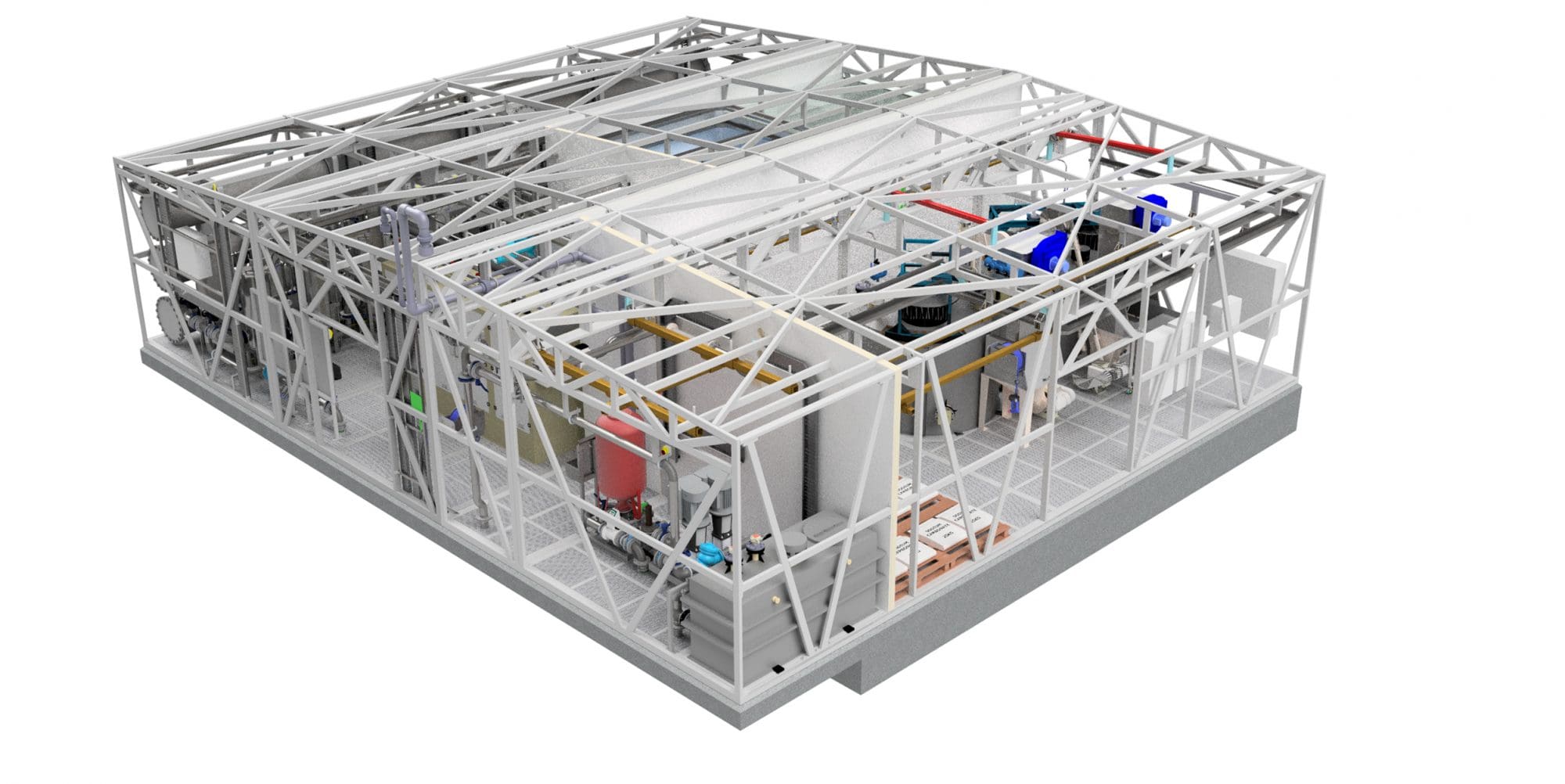

In the end, these tools help engineers optimize designs, anticipate performance and evaluate manufacturability. This allows for quicker time-to-market, lower costs and better product quality. Design for manufacturing (DFM) contributes to product innovation and efficiency by integrating manufacturing considerations into the design process. This approach allows for the identification and elimination of potential manufacturing constraints early on, fostering innovation through more feasible designs. By optimizing designs for manufacturing, DFM enhances efficiency by streamlining production processes and reducing costs. Such an advanced manufacturing simulation was once a pipe dream due to the lack of available tools and manufacturing processes.

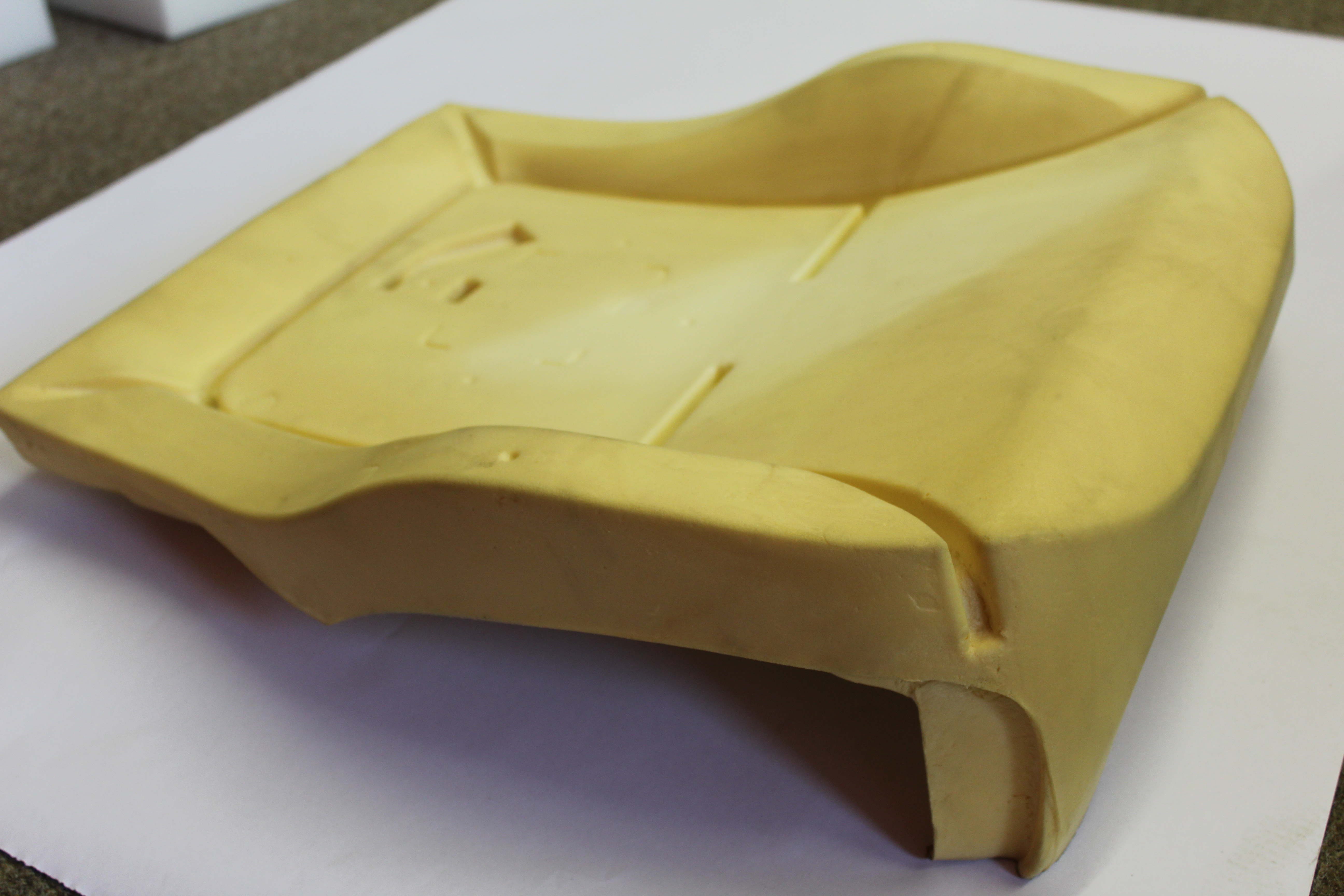

Case Study 1: Automotive Industry

Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. CAD tools analyze material choices, part orientation, tooling needs, and production tolerances to include DFM concepts. Furthermore, CAD models can be translated into machine instructions for CNC (Computer Numerical Control) mills and 3D printers using computer-aided manufacturing (CAM) software. This enables virtual testing and process optimization of manufacturing procedures before the start of actual production.

How Long Does DFM Take?

Design for manufacturing and assembly (DFMA), is an engineering methodology that focuses on simplifying the design of a product to improve ease of manufacture and efficiency of assembly. DfMA is a design methodology that emphasises manufacturing simplicity and assembly efficiency. As a result, a product’s design can be improved to enable faster, safer, more cost-effective, and more efficient manufacturing and assembly. Ultimately, DFM is a collaborative effort that benefits significantly from the expertise of all involved parties. By recognizing and leveraging the insights of suppliers, businesses can make DFM a more effective strategy, improving their overall product development process. In Design for Manufacturing, suppliers also play a crucial role, as they have expertise and deep knowledge about their specific processes and materials.

Federal Circuit Limits Design Patents to Identified Article of Manufacture - JD Supra

Federal Circuit Limits Design Patents to Identified Article of Manufacture.

Posted: Mon, 16 Sep 2019 07:00:00 GMT [source]

DFM Principles

They are only made by a select group of companies, partly due to the need for specialist welding techniques. The company had been waiting for the outcome of an ongoing SMR design competition in the UK – first announced by the Government in 2015 – before it made a decision on the pressure vessel plant. The FTSE 100 company had originally proposed one factory to make heavy pressure vessels for its SMRs and another to make the building blocks of the reactors. Rolls-Royce has scaled back plans to build two new factories for its small modular reactor (SMR) programme in the UK, following delays to a government design competition. Today’s announcement is part of Toyota’s commitment to increase electrification efforts in the U.S. and grows the company’s total investment in its Indiana facility to $8 billion.

Any commercial design process is presumably conducted with at least some attention to how the underlying product will ultimately be produced. But design for manufacturability has evolved into a more formalized, analytical approach to this underlying concern—a dramatic break from historical practices. Embracing cloud technology in the wake of the supply chain crisis induced by COVID-19 is not merely a stopgap measure but a strategic evolution. By merging design and manufacturing more closely than ever, companies can achieve greater efficiency and adaptability. This shift is essential for building more resilient supply chains capable of withstanding future challenges and capitalizing on new opportunities in an unpredictable global market.

This long-term investment that began on the mobile-first foundations of the Android Open Source Project has produced a full mixed reality operating system used by millions of people. Toyota directly employs more than 63,000 people in North America who have contributed to the design, engineering, and assembly of nearly 47 million cars and trucks at our 13 manufacturing plants. By 2025, Toyota’s 14th plant in North Carolina will begin to manufacture automotive batteries for electrified vehicles.

Applying DFM in Real-World Engineering Projects

For instance, the eye is first drawn to the person when looking at Portland, Maine-based Akari Salon & Spa. Then, you see the headline “self-care is important” and a CTA to book an appointment before exploring the rest of the page. This means having it designed so that the eye is drawn to one element over another in a particular order. Sometimes, differentiation means taking a different approach than everyone else. Instead of focusing purely on showing off previous work, Barrow Salon in San Francisco showcases its gorgeous location in the Dogpatch neighborhood.

Early collaboration can significantly reduce production costs and lead times. It can also improve product quality and reliability by ensuring that the product is designed with manufacturing best practices in mind. Moreover, early collaboration fosters better communication and understanding between design and manufacturing teams, leading to more efficient and effective product development processes. DFM occurs early in product development, before tooling and the assembly process, when the product is being designed.

They put their images front and center and let them make a clear first impression on the visitor. Visitors are greeted by a carousel of various images showing people of all genders and ages, showcasing without words that they welcome everyone. On the EDA side, Synopsys Fusion Design Platform™, an integrated and golden-signoff-enabled RTL-to-GDSII design flow, has been qualified for GAA process technologies at major foundries.

Carrier wanted to break down manufacturing siloes and empower their engineering team to leverage the power of aPriori to streamline should costs and quotations without interrupting or delaying the design process. Design for assembly refers to designing a product to maximize how easily it can be assembled and disassembled for repairs and maintenance. This approach often focuses on principles like minimizing the total number of parts used, ensuring that parts are easily insertable, and confining assembly requirements to simple, repetitive motions. However vital, design for manufacturability is only one part of the puzzle when it comes to optimizing product costs and lowering the carbon footprint. Learn more about how to optimize product cost engineering for your organization.

No comments:

Post a Comment